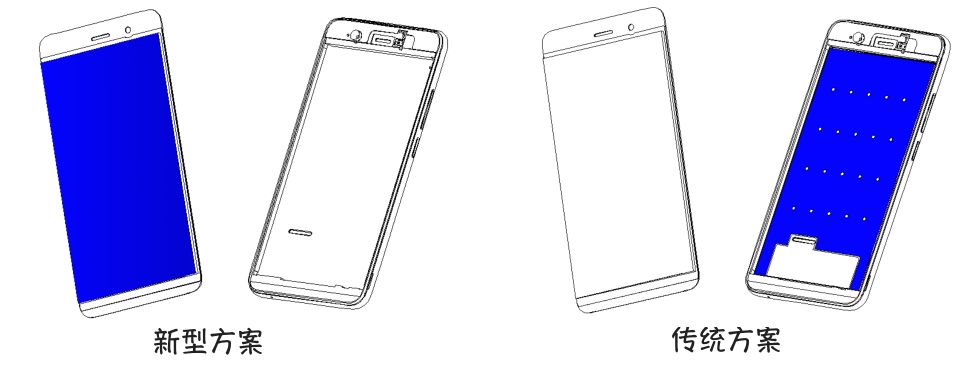

The emergence of ripples/ white spots is a common problem faced by LCD modules at present. The pressing of the fingers, the extrusion of the back cable, and the contact of the shell can cause short-term ripples or permanent white spots. The traditional solution is to apply foam to the shell and use foam to relieve compression or device squeezing. However, it is often difficult to isolate cables and IC chips.

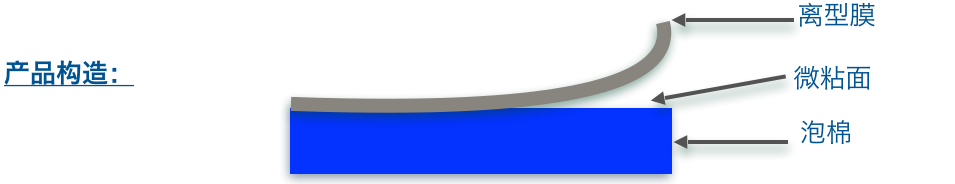

Our new type material, PH-RP series product, stick with its sticky surface to the back of the LCD module. It can absolutely isolate the LCD screen and other components, more effectively to relieve the compression force. The character of micro-sticky ensures that repeated pasting does not tear and affect the backlight. Our products have excellent thickness retention capabilities. The initial thickness can be maintained during continuous extrusion so that it can provide consistent performance.

Product Features:

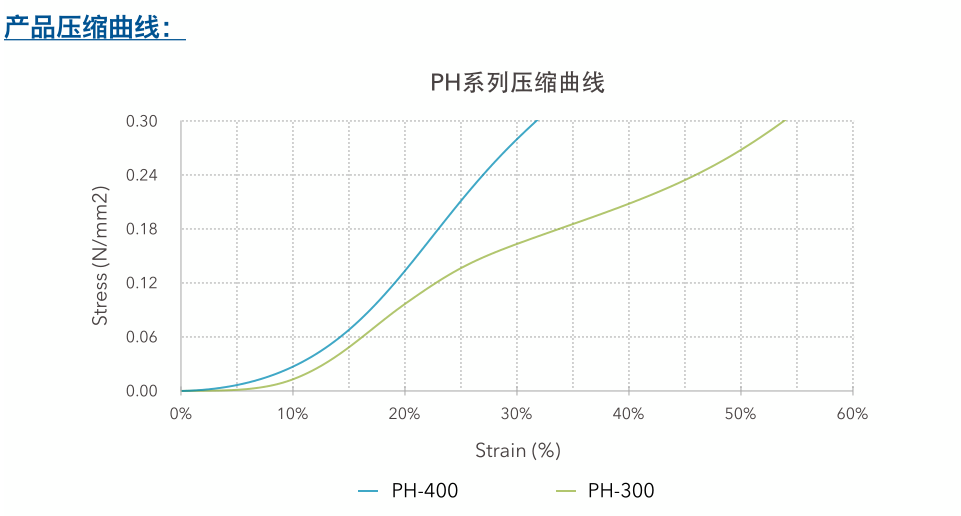

· Ultra-thin thickness, thickness as low as 0.1 to 0.3 mm provides a rich selection of ultra-thin space fills.

· Softness can be adjusted to meet customer needs.

· Micro-sticky surface can be directly sticky to glass or film surface, eliminating the need for tape. It can also be used with graphite.

· It is easy to rework. The surface sticky is strictly controlled so that it can ensure stability of the paste and meet the needs of repeated paste without residues and affecting the backlight.

· No bubbles residue after sticking. The special formulation and process make the foam have good venting function, no bubble residue during the application process. It facilitates the assembly.

· High level of anti-compression deformation assuring the devices of long-term protection.

昇英新材料科技(常州)有限责任公司是专业从事高性能聚氨酯发泡材料研发及生产的公司。我公司具有先进的研发和生产技术,不断开发新的产品和解决方案,以应对客户和市场的需求。